Laser marking of COVID-19 rapid tests

09.08.2021

ACI is a partner of Senova GreenLight

The digital COVID-19 rapid test

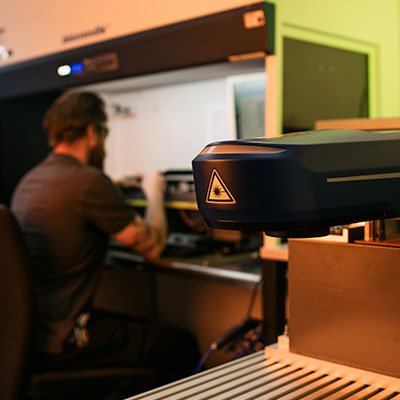

At Senova Gesellschaft für Biowissenschaft und Technik mbH in Weimar, several labelling lasers from ACI Laser GmbH are being used in the GreenLight project. These are integrated into the first fully automated production line for digital COVID-19 rapid tests. Our laser systems are used to mark DataMatrix codes with very high information density as well as plain text and product labelling on the plastic housings of the Senova GreenLight rapid tests.

Requirements for the laser marking system:

- High speed

- High-quality marking result

- Simple integration into the existing production line

High processing speed and labelling quality

Only with the appropriate technology is it possible to achieve a high-quality labelling result at high speed on the given material. UV lasers are used for labelling the rapid tests. The DPL Lexis Marker achieves the desired labelling result in minimal processing time. Four rapid tests are labelled in 12 seconds.

Organic materials such as plastics react very well to the wavelength of 355 nanometres, i.e. a very high-contrast marking can be created on the material. In addition, the low penetration depth protects the material surface. To select the right laser system, extensive labelling tests were carried out in advance in ACI Laser GmbH’s in-house application laboratory.

Special structural feature of the laser station

The laser cell is an airlock with two labelling lasers. They are installed in two separate chambers in a very confined space and simultaneously label the rapid tests. These arrive at the laser station on the conveyor belt in an insertion device and are lifted by the conveyor belt high into the laser’s focus. Once the labelling process is complete, the device is lowered back onto the conveyor belt. The interlocks are enclosed in a light-tight housing, which makes the laser system a safe system in accordance with laser class 1.