A satisfied ACI customer

Powerful and extremely precise

UKP laser technology for the highest demands

ACI Laser’s ultrashort pulse lasers set new standards in precision machining and industrial laser technology. The UKP laser class includes picosecond lasers such as the DFL Brevis Marker, which combines ultrashort pulse durations with the efficiency of a fiber laser.

Thanks to the high intensities of the laser pulses and the short pulse duration, ACI Laser’s ultrashort pulse lasers outperform conventional technology in industrial laser technology. ACI Laser’s ultrashort pulse laser is particularly impressive in the fields of laser material processing and microprocessing.

The right laser for your needs

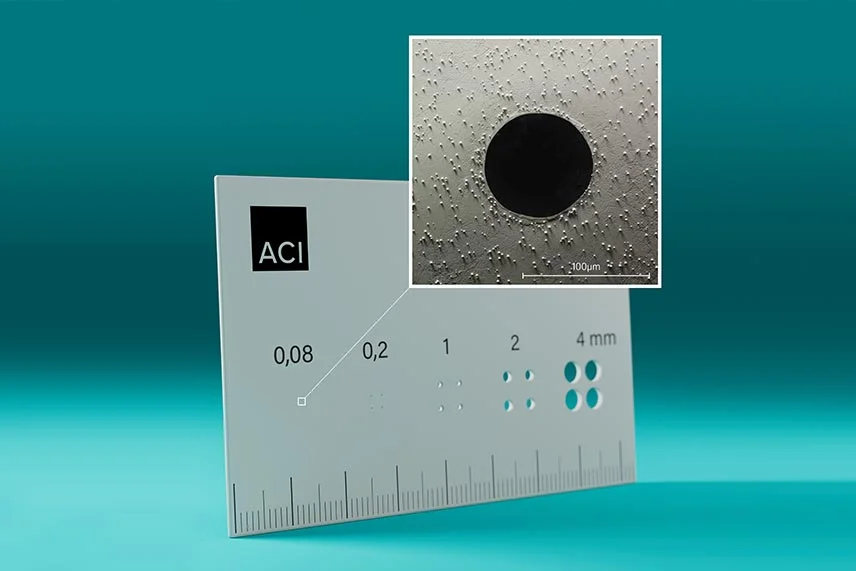

The possible applications of our ultrashort pulse lasers are extremely diverse. Among other things, they are used for precise laser drilling of micro- and nanostructures, clean laser cutting with high cutting quality, and laser structuring to create functional surface structures. In addition, they enable high-quality, high-contrast laser marking on metals, plastics, and other materials.

Compared to similar systems, the ultra-short pulse lasers in the Business Fiber USP product series guarantee extremely short pulses and very high peak pulse power thanks to ultra-short pulse laser technology (UKP laser technology) combined with the advantages of a fiber laser.

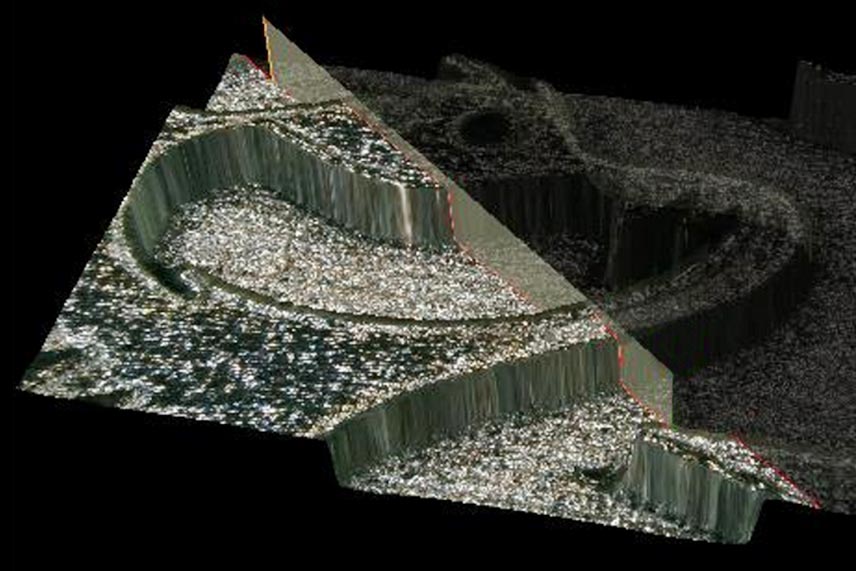

Ultra-short pulse lasers are characterized by maximum precision, enabling the finest structures and details to be created without thermal damage to the material. This property is particularly valuable for demanding applications in micro-machining. The versatility of ultra-short pulse lasers allows a wide range of materials to be processed. This makes them ideal for the manufacture of medical devices, jewelry, and tools.

Cold working with maximum precision

Another significant advantage is what is known as “cold ablation” (cold ablation), which ensures minimal heat input and thus prevents deformation or damage to the workpiece. This technology is particularly important for sensitive materials and applications that require the highest precision. In addition, ultrashort pulse lasers enable permanent and high-contrast markings on various materials, making them ideal for medical technology and other demanding industries.

The ultra-short pulse laser is ideally suited as a tool for precision manufacturing. High-quality processing results can be achieved on metals, polymers, glass, and ceramics. This makes it possible to produce holes with diameters ranging of approx. 50 micrometer to several millimeters.

Thanks to the precise adjustment options of our ultrashort pulse laser—such as laser power, focusability, and pulse shapes—it is very advantageous for targeted material removal on surfaces. Smooth cut edges without breakage and removal results without microcracks or material damage can be achieved.

The strengths of the DFL Brevis Marker ultra-short pulse laser lie primarily in the black marking of stainless steel materials. Due to the low heat input, the USP laser can be used to produce deep black micro markings. When laser marking surgical and medical instruments, UDI-compliant, corrosion-resistant markings of codes, plain text, and serial numbers are possible.

The aim of marking a product or component is to create a label that is permanent, high-contrast, and high-resolution. In addition, it should have minimal impact on the material and cause no change to its properties. These requirements are optimally met by the laser systems in the Business Fiber USP series.

What distinguishes UKP lasers from other laser technologies?

UKP lasers operate at very high power levels of up to several hundred megawatts. However, this power is only transferred to the material in very short pulses lasting a few pico- or femtoseconds. The combination of these properties and their reliably reproducible accuracy makes ultrashort pulse lasers ideal for microstructuring sensitive surfaces.

How does an UKP laser work?

UKP lasers typically use solid-state media to generate ultra-short laser pulses. These are amplified in a pumped laser medium to generate the energy required for material processing. The laser pulse can then be compressed using fiber optics to adjust the pulse duration. If necessary, the wavelength can also be converted, for example to enable optimal absorption by the material being processed.

Are UKP lasers safe to use?

Our laser systems are equipped with a safety device that is certified according to EN ISO 13849 in accordance with functional safety requirements. This enables us to guarantee users the best possible protection against malfunctions.

How are ultra-short pulse lasers controlled?

For complete control of ACI’s UKP laser systems and all laser peripherals, we offer you a powerful and user-friendly solution with our in-house Magic Mark V3 software. The graphically oriented user interface allows for the easy creation of marking content with text, serial numbers, graphics, and codes. The integration of the laser system into automatic production lines is possible with Magic Mark V3 via cross-system software interfaces.

Press ENTER to confirm or press ESC to close