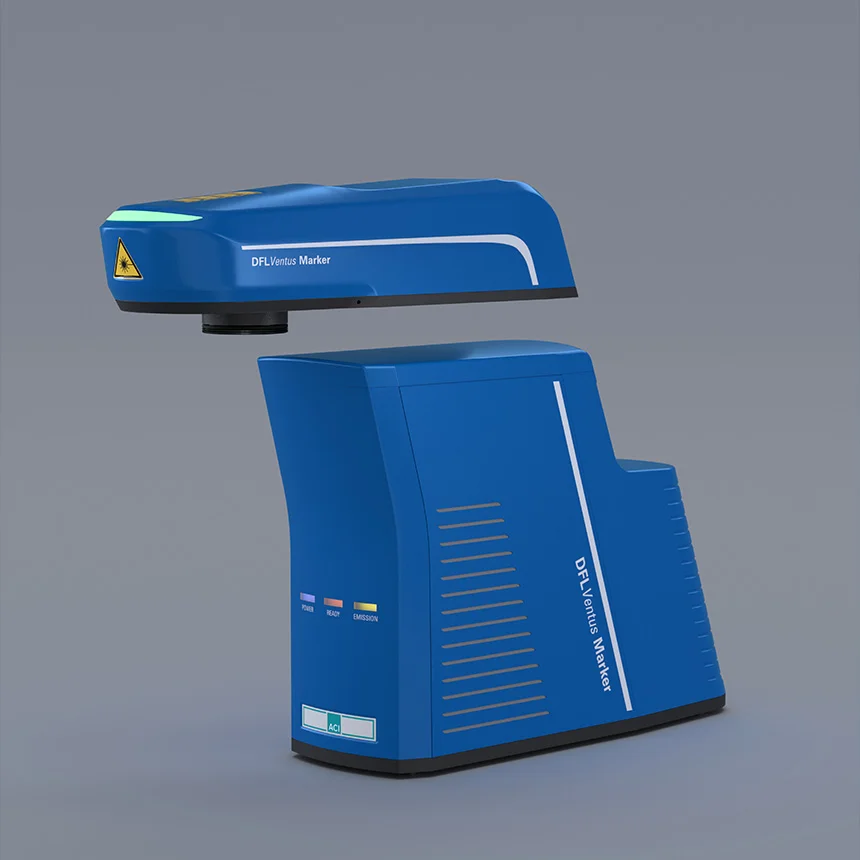

Magic Mark

The laser system is controlled using our in-house Magic Mark laser software. It enables the marking of workpieces with text, graphics, codes (DataMatrix codes, barcodes), serial numbers and logos. It can also be used to apply circumferential marking to rotationally symmetrical components without using an attachment. Intelligent rights management supports the creation of different operator groups. This allows the laser system to be adapted to the respective user requirements. Fully automatic operation with data exchange to various data sources is easily possible when used in automated production lines. The functions of Magic Mark can optionally be extended using plug-ins such as the code or script module.

More about Magic Mark