Customized solutions

User-friendly and flexible

Automated or manual workstation

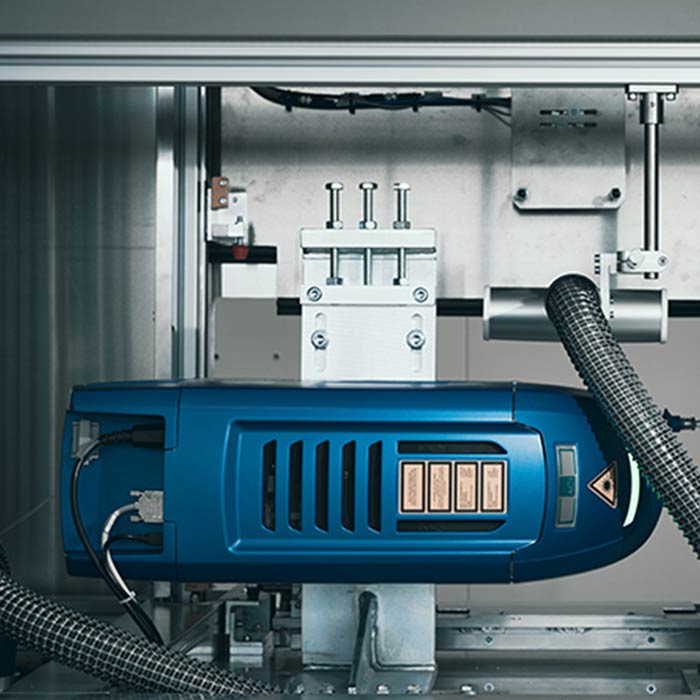

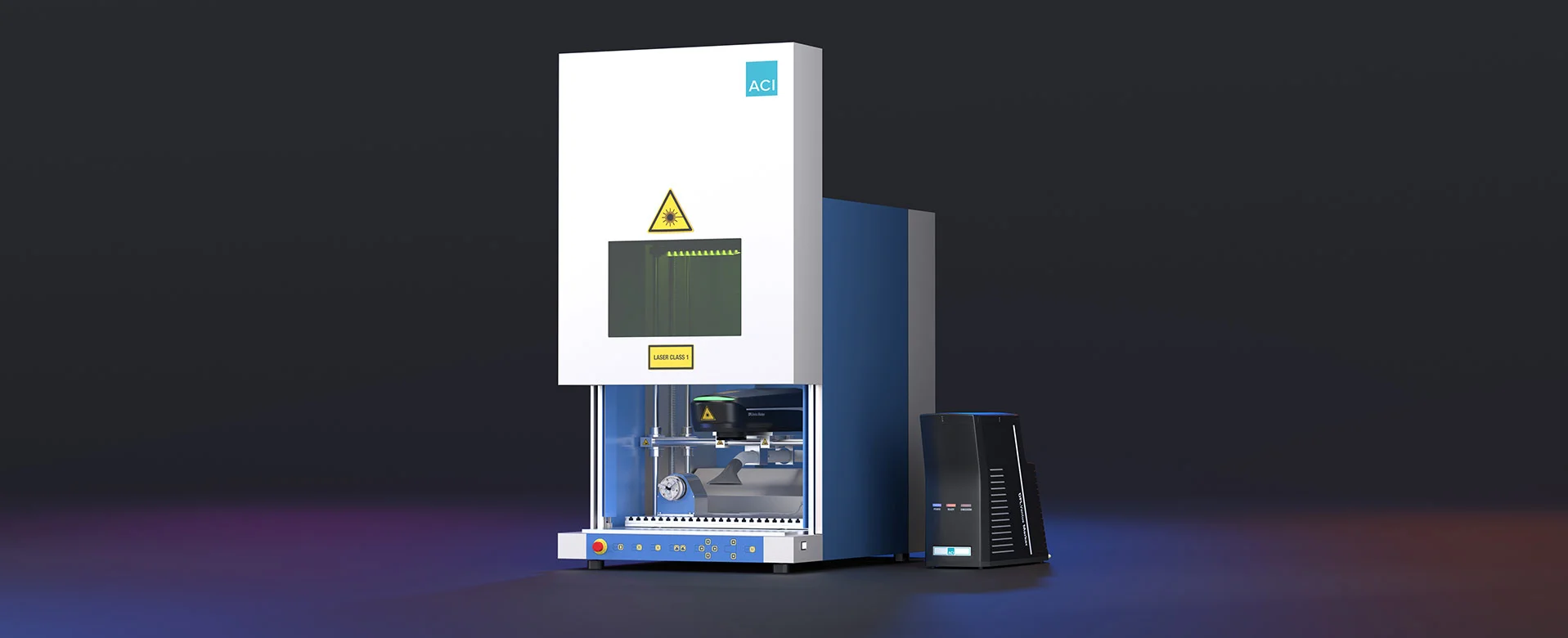

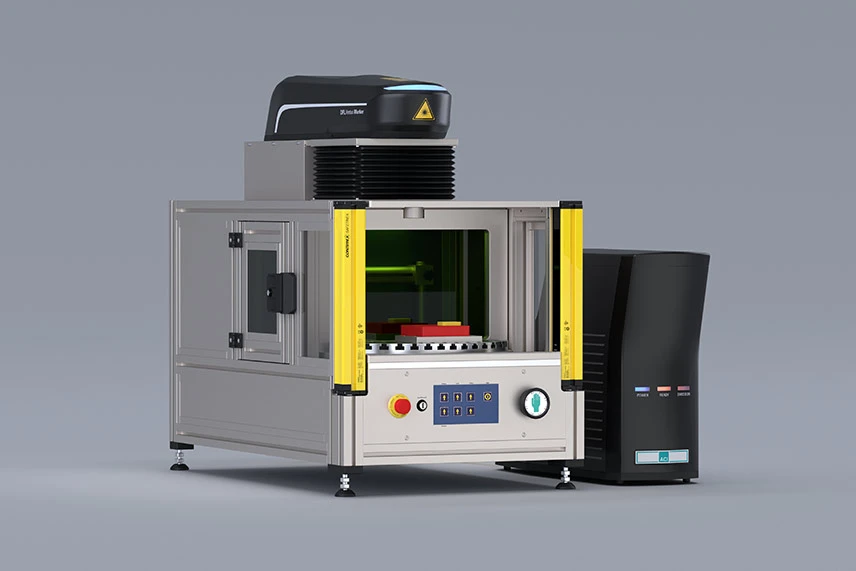

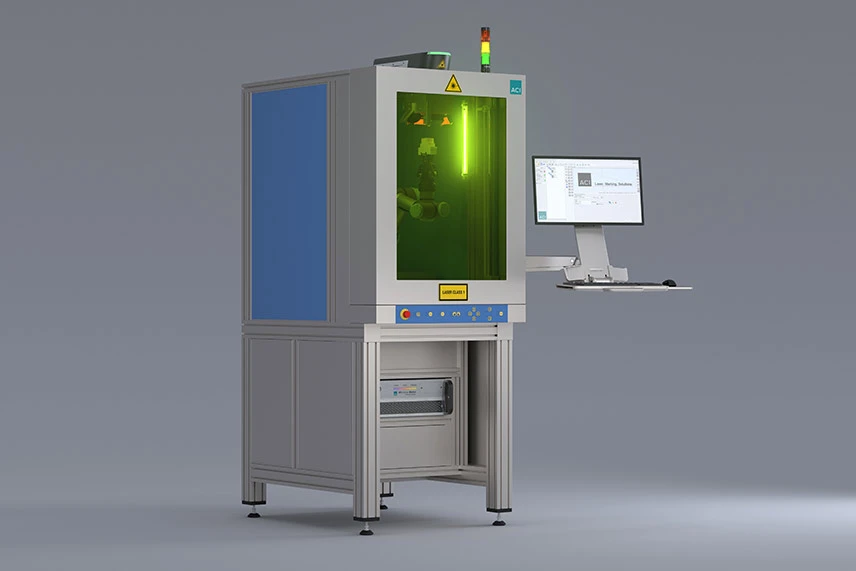

ACI protective housings for laser stations make it possible to operate lasers in accordance with laser protection class 1 without the need for additional safety equipment for these laser stations. With an enclosure, laser systems can be used as a stand-alone workstation or as an integration component in an automated system. The ergonomically optimized design of the table-top workstations and the practical functionality ensure a high level of user satisfaction. All laser stations can be combined with all ACI systems.

The highly flexible protective housing is more standard with an X and Z axis, which is primarily used for processing large, heavy components and products. The Workstation Professional is a turnkey system solution in accordance with laser protection class 1.

The compact Workstation Classic laser workstation is equipped with an integrated, motorized Z-axis as standard, enabling the marking of components of different heights. It is typically used for small to medium quantities.

Our high-performance foil handling system is used when direct laser marking of the material is not possible. Special laser foils and labels can be marked permanently and in high quality in large quantities with the Foil Star.

The modern table-top Workstation RT400 is equipped with a turntable and enables time-saving laser marking in series production. The laser station is used for virtually uninterrupted marking of components.

The Workstation Robotic laser marking station is a complete solution equipped with an ultra-light, compact industrial robot. The integrated robot enables complex motion sequences and fast laser marking of components on multiple sides in all positions.

Laser marking systems can be used for a wide range of applications. The industry requires both integration solutions and manual workstations of laser safety class 1 for use in companies. This manual laser workstation – also known as a workstation – is generally used for manual laser marking of individual items or small series, but also for larger series as part of the automation of laser marking.

In some companies, robot technology is also used in addition to manual loading. Such manual workstations integrate all the necessary peripheral devices (e.g. digital object recognition through image processing) and generally eliminate the need for additional assembly and construction of additional components. Laser marking and marking of components and products with the laser becomes particularly economically attractive with such manual workstations and, depending on the process control, reduces the costs of component post-processing. This can be considered an enormous advantage during procurement. Maintenance service is particularly easy thanks to the excellent accessibility.

Press ENTER to confirm or press ESC to close