A satisfied ACI customer

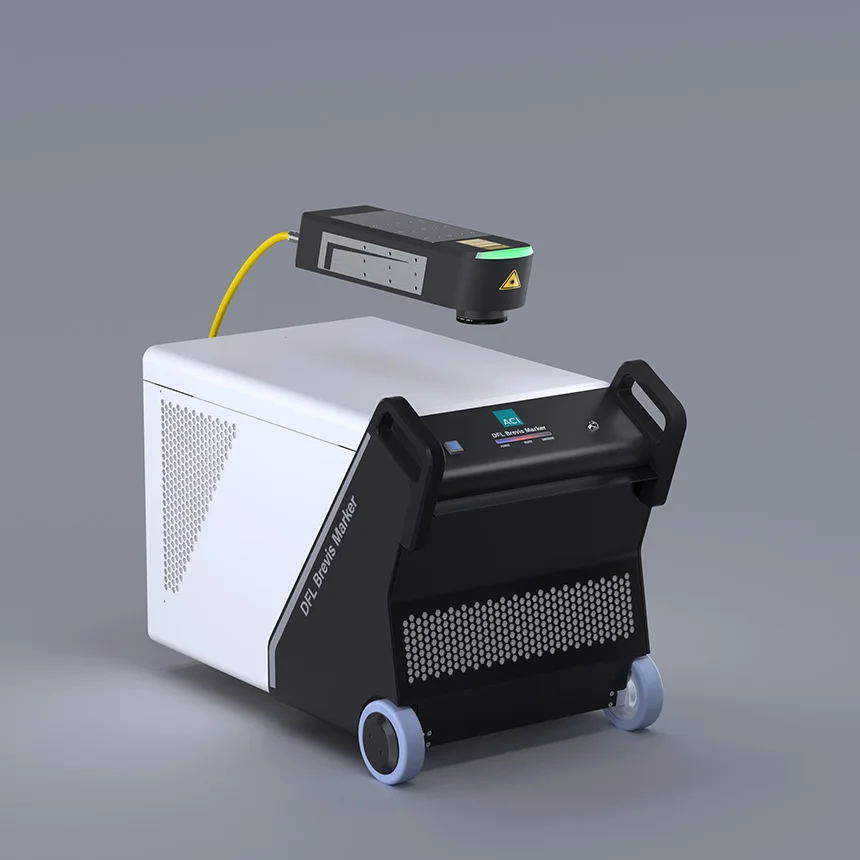

| Material and process | DFL Brevis Marker |

|---|---|

| Temper the metal | |

| Engrave metal | |

| Remove metal | |

| Foam plastic | |

| Carbonize plastic | |

| Engrave plastic | |

| Foil removal | |

| Foil color cover | |

| Glass | |

| Ceramics | |

| Wood, paper, leather |

sehr gut

gut

ungeeignet

UKP-Laser

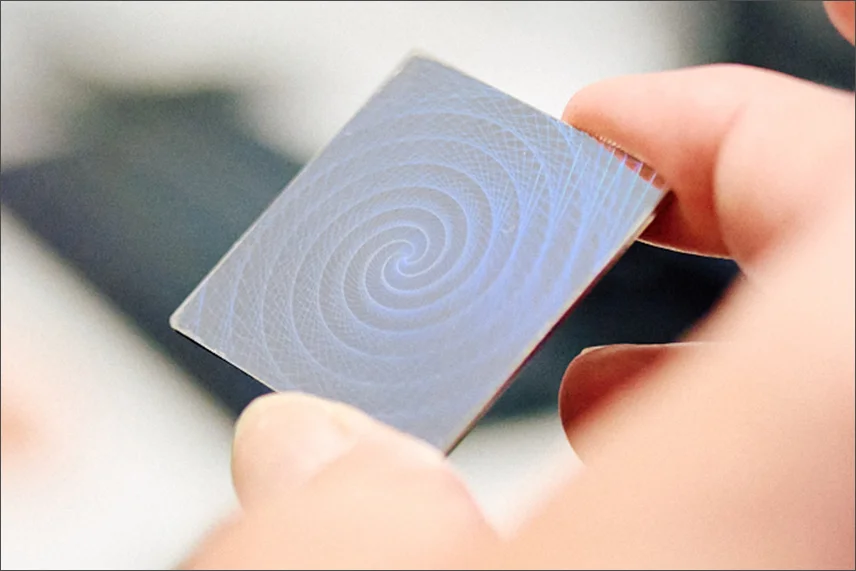

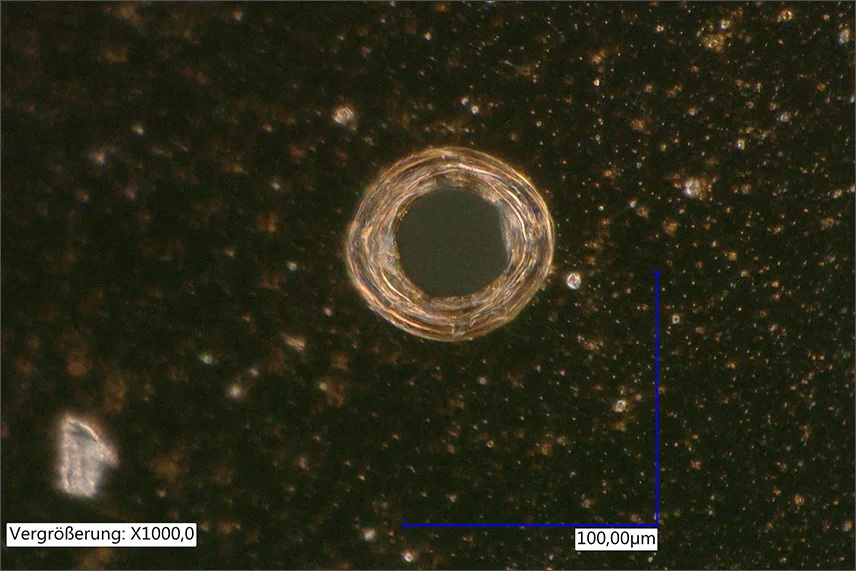

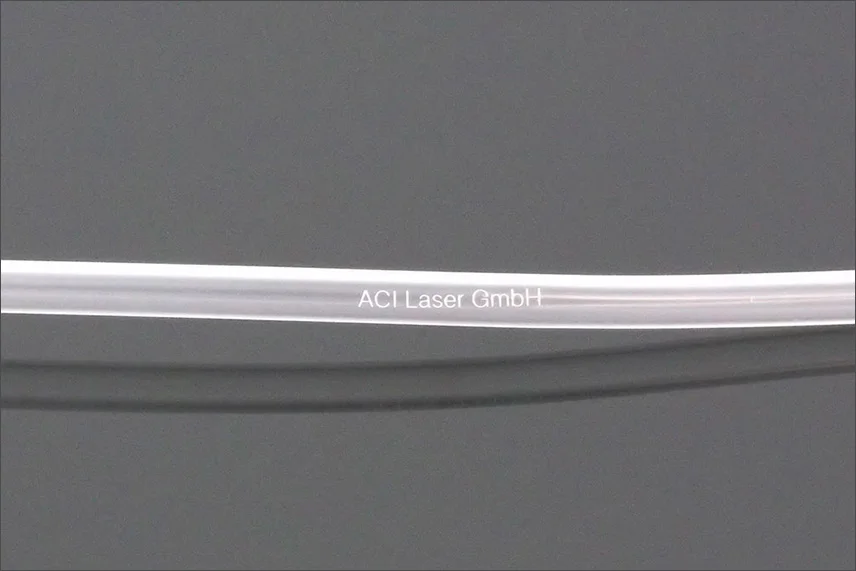

The DFL Brevis Marker is an ultra-short pulse laser that combines a high pulse power with a short pulse duration. This enables it to mark sensitive materials without thermal damage (so-called “cold laser marking”). Laser markings with the DFL Brevis marker are precise, detailed and of high quality.

Download request

| Material and process | DFL Brevis Marker |

|---|---|

| Temper the metal | |

| Engrave metal | |

| Remove metal | |

| Foam plastic | |

| Carbonize plastic | |

| Engrave plastic | |

| Foil removal | |

| Foil color cover | |

| Glass | |

| Ceramics | |

| Wood, paper, leather |

sehr gut

gut

ungeeignet

Magic Mark

The laser system is controlled using our in-house Magic Mark laser software. It enables the marking of workpieces with text, graphics, codes (DataMatrix codes, barcodes), serial numbers and logos. It can also be used to apply circumferential marking to rotationally symmetrical components without using an attachment. Intelligent rights management supports the creation of different operator groups. This allows the laser system to be adapted to the respective user requirements. Fully automatic operation with data exchange to various data sources is easily possible when used in automated production lines. The functions of Magic Mark can optionally be extended using plug-ins such as the code or script module.

Symbolische Verpackung für die Lasersoftware Magic Mark V3

All laser systems are equipped with a safety device (SD) certified to EN ISO 13849 in accordance with the requirements of functional safety, thus guaranteeing the user the highest possible protection against malfunctions and a safe condition of their laser system. (EN 13849 PLe Cat. 4).

When marking a product or component, the aim is to create a marking that is permanent, high-contrast and high-resolution. In addition, it should only cause minimal stress to the material or change its properties. These requirements are optimally met by the laser systems in the Business Fiber USP series.

Download request

A satisfied ACI customer

ECOM Instruments GmbH | Werner Gebert

Head of Operations

Pepperl+Fuchs SE | C. Ahlheim

Project Expert Process Technology Development (PTD)

The Engraving Crew | T. Evans

Goldschmiede Arthur Müller | S. Thon

Owner

STILLE Präzisionsmesstechnik GmbH | M. Leipold

Commercial Director

Technomatik GmbH | J. Gaßner

Head of Process development and tool, jig & fixture manufacturing

Diato GmbH | R. Heydel

Production Manager

Harmonic Drive SE | T. Knapp

Production technician mechanics

von den Steinen GmbH & Co. KG Präzisionsschneidwerkzeuge | U. Bäcker

Technical consulting

MAK | T. Lammert

Technical product designer

HoLaP | L. Chalet

Manager

Press ENTER to confirm or press ESC to close