ACI Laser becomes umati partner – OPC UA integration for networked laser systems

12.02.2026

As an umati partner, ACI Laser is strengthening the standardized OPC UA integration of its laser systems. The aim is to simplify integration into networked production environments and to provide long-term support for interoperability in Industry 4.0 processes.

Networked manufacturing requires standardized interfaces

Modern manufacturing is no longer just about precise machining results. Equally important is how quickly and reliably machines can be integrated into existing production environments – and how well they work with higher-level systems.

Through the umati partnership, ACI Laser supports open standards based on OPC UA. The aim is to simplify the integration of laser systems into networked production environments and to strengthen interoperability in Industry 4.0 applications.

Why standardization matters in practice

In many projects, the greatest effort is not required by the machine itself, but rather by connecting it to existing IT and automation environments. Different interfaces, individual protocols, and project-specific data formats often lead to additional engineering, coordination effort, and longer commissioning times. A cross-manufacturer standard offers a clear advantage here: when machines “speak the same language,” integration projects can be implemented more quickly and are easier to maintain in the long term.

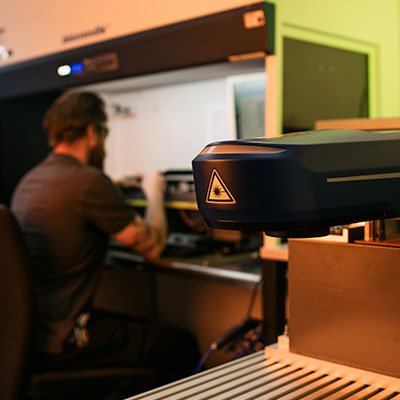

Laser systems are increasingly being integrated as part of networked production processes.

umati and OPC UA – the common language for machines and IT

umati (universal machine technology interface) stands for standardized machine interfaces based on OPC UA. This allows defined machine information to be transmitted uniformly and securely to higher-level systems, such as manufacturing or control station systems.

There is a standardized data model for laser systems (OPC UA Companion Specification for Lasers, OPC 40530). It describes typical information such as operating status (“running”/“stopped”), errors and warnings, maintenance instructions, recipe and parameter data, activity logs, and status and consumption values in a uniform structure.

umati also supports manufacturer-independent detection and automated integration of machines (“plug-and-produce”). Mechanisms such as encryption and access control contribute to secure communication.

The added value for ACI customers: faster integration, more transparent operation

ACI laser systems for marking, engraving, and trimming can be seamlessly, quickly, and securely integrated into customer IT environments via umati without the need for complex special solutions. This simplifies the integration process, saves engineering resources, and reduces project costs. This results in concrete advantages for operators and integrators:

+ Less integration effort thanks to standardized interfaces

+ Faster commissioning and clearer project planning

+ Greater transparency regarding machine status and process information

+ Simpler maintenance and reduced dependence on individual adjustments

+ Future-proof connectivity for growing and networked production landscapes

Laser systems as part of networked production processes

ACI Laser develops and manufactures its laser systems entirely in Germany – from compact workstations to integration solutions for automated production lines. In addition to precision, energy efficiency, and durability, integration into digital production environments is becoming increasingly important.

With the umati partnership, ACI Laser underscores its commitment to making laser technology not only powerful, but also interoperable and capable of long-term integration – in line with the requirements of modern production.

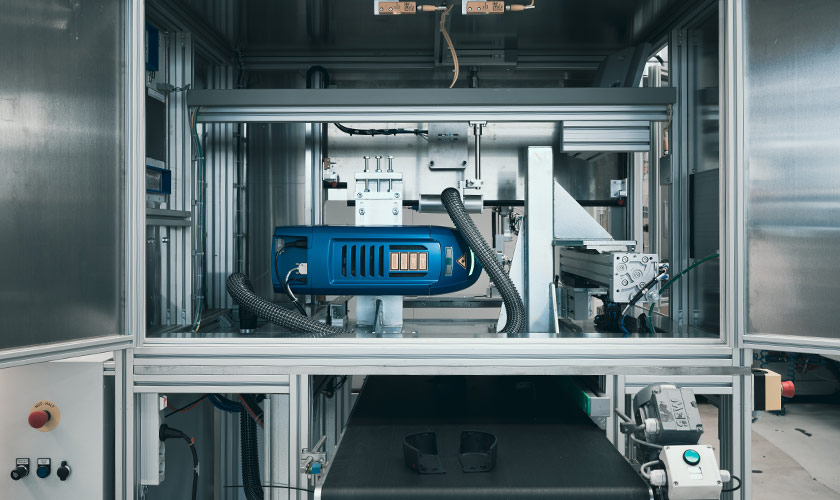

Automated laser marking during the production process – integrated, controlled, and networked.

Next step towards Industry 4.0

Through its umati partnership, ACI Laser is committed to open, practical standards for Industry 4.0 connectivity. The aim is to make laser systems not only precise in their application, but also efficient in their integration into digital production environments.

umati offers clear advantages in this regard: interoperability, secure and simplified data integration, and a reliable foundation for smart factory concepts and data-driven production. Continuous development across key technology areas is resulting in scalable integration approaches – and thus greater investment security for networked production environments.